Lifting Services

We have a Team of Highly Qualified Skilled and Experienced

We summarized the needs as the following:

Inspection services:

It’s necessary to inspect your lifting equipment frequently and give them their appropriate.

Certification to ensure and maintain safe lifting operations.

Lifting equipment require constant thorough examination every 6 & 12 months in accordance with Examination scheme.

Lifting Appliances

• Mobile cranes

• Portal cranes

• Overhead/gantry crane

• Self-loading arms/ HIAB

• Fixed lifting beams & Jacks

• Mobile Aerial Platforms

• Hoists

• Pad eyes (fixed structural)

• Forklifts

• Side booms

• Beam trolleys

• Sheave blocks

Lifting Accessories

• Wire rope sling and Webbing sling

• Chains and chain slings

• Shackles

• Beam- and Plate clamps

• Eye bolts & swivel rings

• Hoist rings

• Wedge sockets

• Safety harnesses

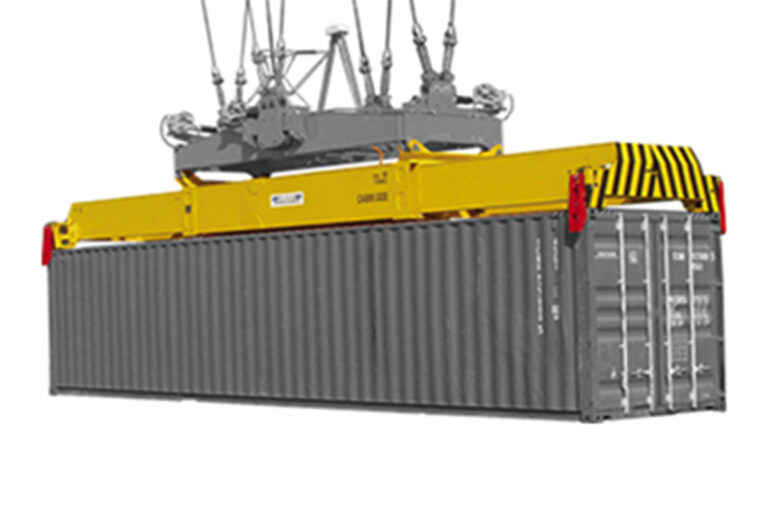

• Spreader beams

• Hooks

• Pad eyes and bolts

Lifting Equipment

• Containers

• Skids

• Skips

• Drum racks

• Baskets

• Pipe racks

• Big bags.

Hiring lifting equipment

is the solution for short-term period that could accomplish the demand of a Single item, Based on client’s needs for cost control.

• Six Monthly LOLER SI 2307 Rig Survey.

• Drilling Handling Tools Inspection.

• NDT Inspection (MPI, DPI, UT).

• Derrick Inspection.

• Crane Inspection.

• Dropped Object Surveys.

• Equipment Supply.

• Lift Planning.

• Training Services.

• Engineering and Consultancy.

• Pad eye Inspection.

• Runway Beam Inspection.

• CCU Inspection DNV 2-7.1 BSEN 12079.

• Lifting Beam Inspection.

• Forklift Inspection.

• Over Head Travelling Crane Inspection.

• Winch Inspection.

• BOP Crane Inspection.

• Top Drive Inspection.

We have a Team of Highly Qualified Skilled and Experienced